Shop

A320 General Familiarisation with CFM56, V2500 & PW6000

£375.00

Our Courses Scale Perfectly To Any Device

About our Online Self-Study Course

The A320 General Familiarisation course with CFM56, V2500 & PW6000 powerplants, has been designed to give you a complete technical overview of all aircraft systems. The course covers all mechanical and avionics systems, This self–study online A320 General Familiarisation course with CFM56, V2500 & PW6000 powerplants, will take approximately 40 hours of study. Students must pass the multi-choice question at the end of each ATA chapter before the next ATA chapter is unlocked. A completion certificate is issued on successful completion of the course.

Our A320 General Familiarisation course with CFM56, V2500 & PW6000 powerplants, is produced to a minimum of ATA 104 Level 1 and EASA Part 66 Level 1 knowledge levels and course completion time will be approximately 40 hours. This information is stated on the certificate.

You have 12 months from enrollment to begin the course and after starting, 6 months to complete the course. You have a further 90 days to review the course after completion.

Click on the DESCRIPTION below for course syllabus and more details. Please click here to view our sample course. You have a further 90 days to review the course after completion.

When checking out, please ensure you use the student’s name. To enroll multiple students in the same course, please make separate transactions or contact us for team discounts.

Description

A320 GENERAL FAMILIARIZATION COURSE WITH CFM56, V2500 & PW6000 POWERPLANTS

ABOUT

Our A320 General Familiarisation course with CFM56, V2500 & PW6000 powerplants, meets ATA 104 Specification Level I: General Familiarisation; A brief overview of the airframe, systems and powerplant as outlined in the Systems Description Section of the Aircraft Maintenance Manual.

The A320 General Familiarisation course with CFM56, V2500 & PW6000 powerplants, also complies with EASA’s knowledge LEVEL 1 definition as contained in Regulation EU No. 1321/2014, Part 66, Appendix III Basic Knowledge Requirements;

A familiarization with the principal elements of the subject, with the objective;

(a) The applicant should be familiar with the basic elements of the subject.

(b) The applicant should be able to give a simple description of the whole subject, using common words and examples.

(c) The applicant should be able to use typical terms

This self-study online A320 General Familiarisation course with CFM56, V2500 & PW6000 powerplants, will take approximately 40 hours of study. Students must pass a quiz at the end of each ATA chapter before the following ATA chapter is unlocked. A completion certificate is issued on successful completion of the course.

Course objectives: upon completion of the course, the student will be able to identify safety precautions related to the airframe, it’s systems and powerplant.

Identify maintenance practices important to the airframe, it’s systems and powerplant

Define the general layout of the aircraft’s major systems.

Define the general layout and characteristics of the powerplant.

Identify special tooling and test equipment used with the aircraft.

SYSTEM REQUIREMENTS

Our courses scale perfectly to PC, Laptop, tablet, android and iPhone. You must have an internet connection to use our courses.

STUDY TIME

Course completion time varies with the individual; however, we estimate approximately 40 hours will be required. You have 6 months to complete the course and can stop and restart at the same position with your progress saved. Once completed you will have a further 90 days to review the course.

SUPPORT

Should you require any assistance during your course, please contact us and we will assist you during normal working hours.

WHY USE OUR GENERAL FAMILIARIZATION COURSES?

Our online A320 General Familiarisation course with CFM56, V2500 & PW6000 powerplants, provides an excellent solution for training engineers or company support staff, giving the required in-depth aircraft type knowledge with the advantage of distance learning.

WHY BUY FROM US?

Our A320 General Familiarisation course with CFM56, V2500 & PW6000 powerplants, is designed and produced by EASA and UK CAA B1/B2 Engineers, Type instructors and Part 147 Training Managers. We ensure each course covers all relevant ATA chapters.

DETAILED COURSE SYLLABUS

The A320 General Familiarisation course with CFM56, V2500 & PW6000 powerplants, begins with an aircraft type introduction, then covers each ATA chapter to approximately Part 66 Level 1 or greater if required;

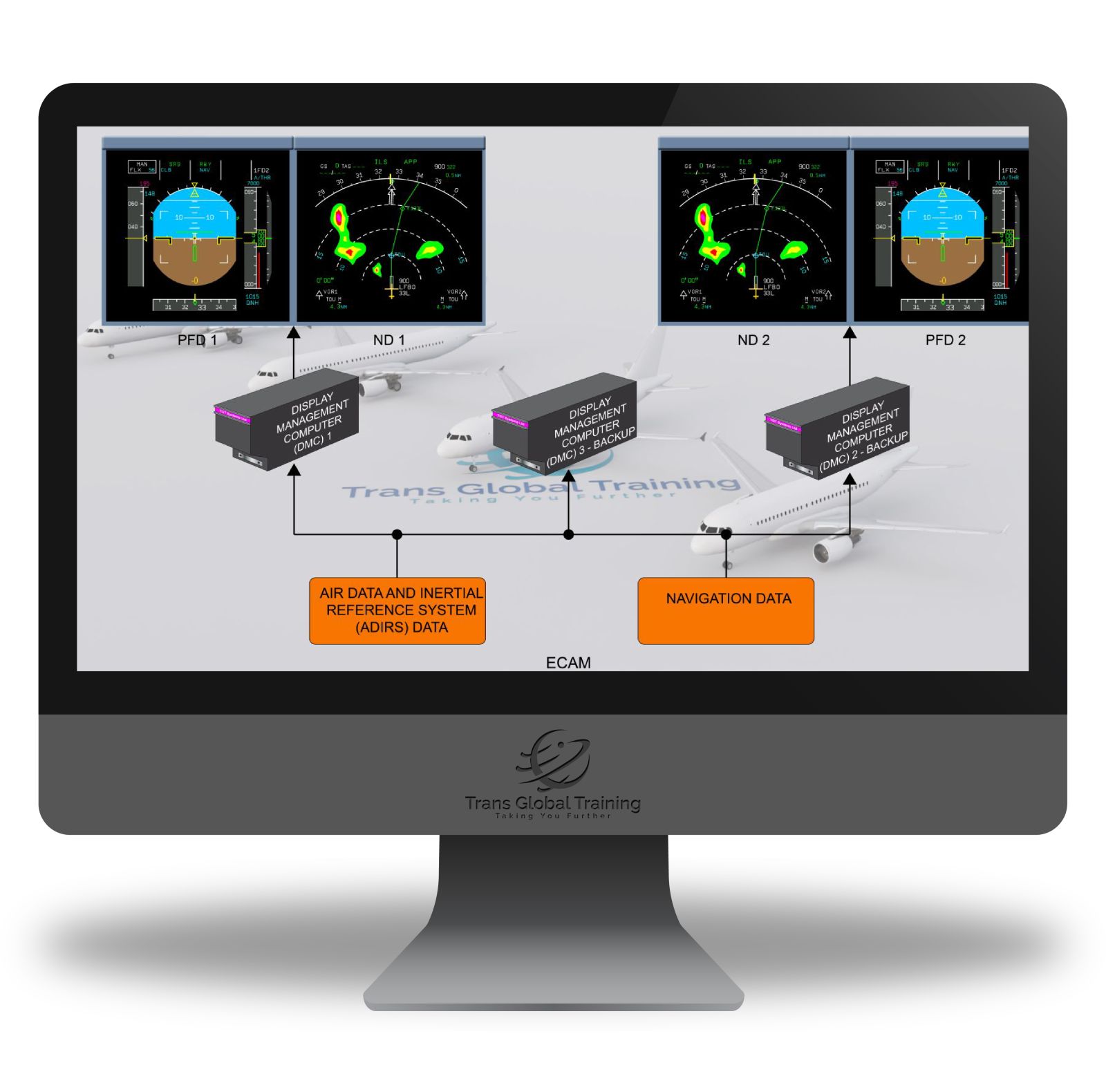

ATA 31 INDICATING/RECORDING SYSTEM – Electronic Instrument System, ECAM, System Data Acquisition Concentrators (SDACs), Display Management Computers (DMCs), Flight Recorders, AIDS, Component Locations and Maintenance/Test Facilities.

ATA 24 ELECTRICAL SYSTEMS – AC + DC Normal, Abnormal and Emergency Generation, Distribution and control, Component Locations and Maintenance/Test Facilities.

ATA 34 ADIRS AND STANDBY INSTRUMENTS – Air Data/Inertial Reference System (ADIRS) and standby instruments, Dependent Position Determining Systems, Landing Aids, Independent Position Determining Systems, Air Data Inertial Reference Units (ADIRUs), Standby Instruments, Digital Distance and Radio Magnetic Indicator (DDRMI), Integrated Standby Instrument System (ISIS), GPS, ATC/Traffic Alert and Collision Avoidance System (TCAS), DME, ADF, VOR, ILS, Marker Receivers, Ground Proximity Warning System (GPWS), RAs, Weather Radar (WXR) and Predictive Windshear (PWS), Component Locations and Maintenance/Test Facilities.

ATA 22 AUTOFLIGHT – Flight Management (FM), Flight Guidance (FG), Flight Augmentation, Fault Isolation and Detection System (FIDS), Panel Location/Control and Indicating, Component Locations and Maintenance/Test Facilities.

ATA 46 AIR TRAFFIC INFO MANAGEMENT SYSTEMS – System Architecture, Panel Location/Control and Indicating, Component Locations and Maintenance/Test Facilities.

ATA 23 COMMUNICATIONS SYSTEMS – Radio Communication (VHF, HF, SATCOM, Service Interphone, Flight Interphone, Passenger Address (PA) Cabin Interphone, Solid State Cockpit Voice Recorder (SSCVR), Cabin Intercommunication Data System (CIDS), Panel Location/Control and Indicating, Component Locations and Maintenance/Test Facilities.

ATA 33 LIGHTS SYSTEM – cockpit lighting, cabin lighting and signs, emergency lighting, cargo and service compartment lighting, exterior lighting, and Maintenance/Test Facilities.

ATA 51 – Structures.

ATA 29 HYDRAULIC POWER SYSTEM – Green, Yellow & Blue Systems, Reservoirs, Engine Driven Pumps (EDP), Electric Pumps, Power Transfer Unit (PTU), Fire Shut-Off Valves, Ram Air Turbine (RAT), Component Locations and Maintenance/Test Facilities.

ATA 32 LANDING GEAR – Extension & Retraction, Braking, Steering, Panel Location/Control and Indicating and Component Locations.

ATA 27 FLYING CONTROLS – Flight Control Surfaces, Controls, Indicating, Fly-by-wire Principles, Flight Controls Architecture, Surfaces, Flight Control Laws, Mechanical Back-Up, Slat and Flap Systems, Computers, Actuators, Maintenance and Test Facilities.

ATA 52 – DOORS.

ATA 25 – EQUIPMENT AND FURNISHINGS.

ATA 35 OXYGEN SYSTEMS – Crew Oxygen System, Passenger Oxygen Systems (Chemical Generator Units), Portable Oxygen System.

ATA 38 WATER AND WASTE SYSTEMS.

ATA 28 FUEL SYSTEM – System Introduction, Controlling Indicating, Refuel/Defuel, Component Location, Maintenance and Test Facilities, Fuel Tank Safety.

ATA 26 FIRE PROTECTION SYSTEMS – General System Information, Engine Fire Protection, APU Fire Protection, Avionics Compartment Smoke Detection, Cargo Compartment Smoke Protection, Lavatory Smoke Protection, Cabin Fire Protection, Maintenance and Test Facilities.

ATA 49 APU – Controlling indicating, component location, maintenance and test facilities.

ATA 71 POWERPLANT – Power Plant Introduction and Installation, Modular Concept, FADEC, EIU/EVMU, Thrust Reverser System, Control and Indicating, Component Location, Maintenance and Test Facilities, Lubricants and Fuel, Storage and Preservation.

ATA 36 PNEUMATIC SYSTEM – System Introduction, Controlling Indicating, Component Location, Maintenance and Test Facilities.

ATA 21 AIR CONDITIONING SYSTEM – Ventilation and Pressurization, Air Conditioning System, Air Conditioning Packs, Zone Temperature Regulation System, Avionics Ventilation, Controlling and Indicating, Cargo Ventilation and Heating System, Component Location, Maintenance and Test Facilities.

ATA 30 ICE AND RAIN PROTECTION – System Introduction, Wing Ice Protection, Engine Air Intake Ice Protection, Probe Ice Protection, Windows Anti Icing and Defogging, Wiper System, Drain Mast Ice Protection, Ice Detection, Controlling Indicating, Maintenance and Test Facilities.